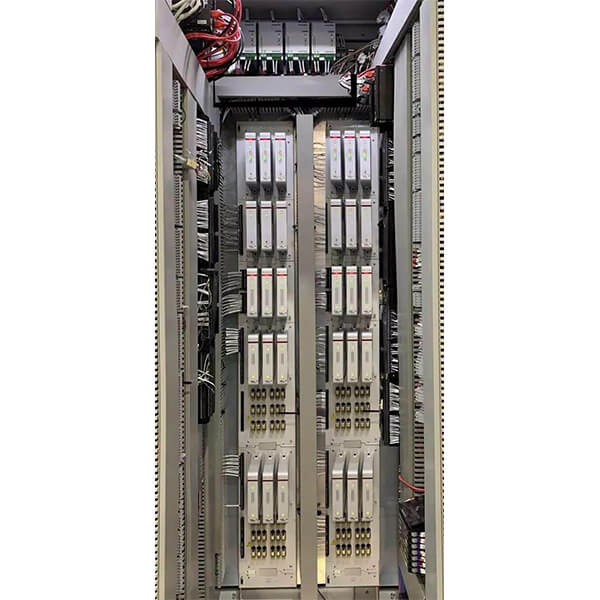

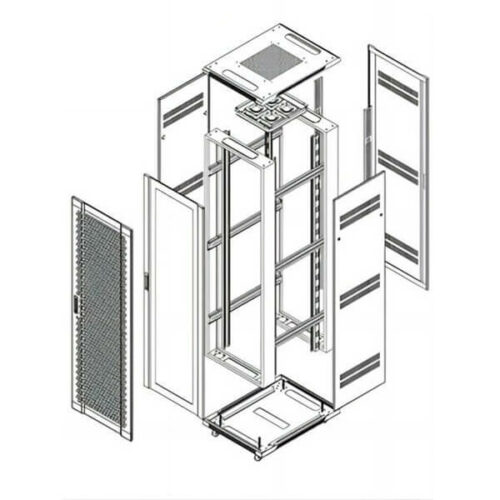

The Remote IO Panel is a state-of-the-art industrial automation product designed to facilitate remote input/output operations in industrial environments. It is an advanced and reliable solution that provides a simple and efficient means of connecting multiple sensors and actuators to a central control system.

This product is designed to withstand harsh industrial conditions, ensuring maximum uptime and minimizing maintenance and downtime. It is compact and lightweight, making it easy to install and integrate into existing automation systems. With a wide range of communication protocols and a user-friendly interface, the Remote IO Panel is the perfect solution for industrial automation applications.