Whatoop Electrical Cabinet

An electrical cabinet is a critical component in modern power distribution and control systems. It houses electrical devices, such as switches, circuit breakers, and control panels, to provide protection against electrical hazards, dust, and moisture. Furthermore, electrical cabinets ensure the safe and efficient operation of electrical equipment, making them indispensable in various industries and applications.

At Whatoop, we specialize in manufacturing high-quality electrical cabinets, backed by our extensive experience spanning over three decades. Our commitment to excellence has led us to produce more than 3,000 electrical cabinets per year, catering to the unique needs of over 200 clients across different sectors. From power plants to manufacturing facilities, our electrical cabinets are designed to withstand the most demanding conditions, ensuring reliability and performance.

Our electrical cabinets have achieved outstanding results and have earned various certifications, such as CCC, CE, UL, and RoHS, demonstrating our commitment to quality and adherence to international standards. Additionally, our expertise in communication protocols, including Profibus, Ethernet, and IEC61850, allows us to provide tailored solutions that meet the evolving demands of modern power systems.

Featured Electrical Cabinet

Electrical Cabinet Features

We provide low-voltage and medium-voltage switchgear for areas including Agriculture, manufacturing, automotive, logistics…

Whatoop Electrical Cabinet Application

Metallurgical Industry

Chemical Industry

Airport

Power Plant

New Energy Field

Residential Building

Steps To Custom Electrical Cabinet

Order Review & Confirmation

Upon receiving an order, we carefully review it to ensure that we fully understand the customer’s requirements. We then confirm the order with the customer and send a confirmation letter.

We have a team of experienced engineers who develop a detailed design for the switchgear system. This ensures that the system meets the required specification and is customized to the customer’s needs.

We manufacture and assemble the switchgear system in-house, using state-of-the-art equipment and skilled technicians. We perform quality control inspections during the production process to ensure that the system is built to the required standards.

We conduct a series of tests to ensure that the switchgear system operates safely and meets the required specification. Once testing is complete, we ship the system to the customer’s site.

We provide shipping and installation services to ensure that the switchgear system is installed correctly and safely. We provide documentation and support to assist the customer in the installation process.

After-sales Support

We provide after-sales support to our customers, including training on how to operate and maintain the switchgear system, troubleshooting and repair services, and ongoing maintenance and service contracts.

Electrical Cabinet FAQ Guide

In the world of operational technology (OT), certain standards and qualities such as reliability, security, maintainability, and standards compliance are critical. These standards are mainly applicable to electrical equipment for monitoring and controlling various types of machinery. These devices must meet specified requirements to ensure efficient operation.

An electrical cabinet is essentially a storage unit that houses the electrical components needed to automate a machine or production process. It serves as the central point of control, enabling the various mechanical components to operate seamlessly.

Electrical cabinets are an integral part of any industrial or civil building, from power plants to substations, from transmission systems to distribution to power consumers. Used as a place for installing and protecting electrical switchgear and control equipment, it is a place for connecting and distributing electricity to buildings, ensuring that electrical equipment is isolated from users. Electricity during operation.

Can be made of metal or composite panels of different sizes and thicknesses as required. In normal applications, electrical cabinets usually have static electricity or wrinkles of different colors according to the field of use or design requirements.

According to the function, structure, and purpose of the electric cabinet, the electric cabinet can be divided into the following common types:

1) Building main distribution cabinet (MSB)

The main distribution cabinet is manufactured according to IEC 60439-1 and IEC 60529 standards. Electrical cabinets are made of galvanized steel and powder coated. The electric cabinet cover, side cover, detachable cabinet back panel, and other components are convenient for users to install and maintain. The layout of the equipment in the electrical cabinet can be adapted to the needs of each customer in terms of the form of the electrical cabinet. Designed for indoor use, the cabinet can distribute power to high-capacity loads, with the advantage of a modular design placed side by side to create a power distribution system including blocking access, and zoning. and distribution room.

2) Central control cabinet

Central control cabinets are available in two types: fixed and non-fixed (pull and pull back)

Control and display of equipment used in electrical cabinets such as soft starters, inverters, direct starters, star/delta starter groups, transformer starting devices, and protection and programming devices. The frame and fish cover are made of galvanized steel and painted with electrostatic paint. Control and protection of industrial and irrigation engines by electrical means.

The electrical cabinet has the following operating mechanisms: on-site or remote operation to turn off and reverse the motor, and on-site or remote operation to change the speed of the engine.

3) Switchgear – ATS

The power distribution cabinet is used in areas that require a continuous power supply to the load. When there is a problem on the grid side, it supplies power to the load. The commonly used backup power source is a generator. In the case of an ATS, the electrical cabinet is responsible for automatically switching power from the grid to a backup source to feed the active load source.

– Rated voltage: 380V / 415V

– Rated current: 1600A / 2000A / 2500A / 3200A / 6300A

– Switching time: 5 ~ 10s

4) Power distribution cabinet (DB cabinet)

Electrical cabinets are designed for the first floor of workshops, factories, or distribution buildings. Therefore, the power distribution cabinet is compact in structure, elegant in appearance, safe, and convenient in operation. DB electrical cabinets are designed to create favorable conditions for the selection of use in buildings. The cabinet is divided into three colors: blue, red, and yellow, which are convenient for installation and later maintenance.

5) Capacitance compensation cabinet

The cabinet compensates for the workshop load of the production line, and the large commercial side can handle 600kVAR. Capacitance compensation protection control mode meets customer requirements.

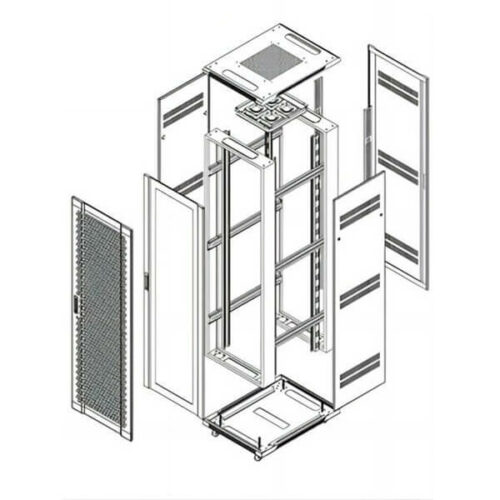

6) Rack cabinet

Rack or network cabinet, different from the cabinets used in general households, rack (network cabinet) is a special cabinet, they are used to install routers, switches, servers, and other network equipment. The device is protected from the external environment. The cabinet (network cabinet) is made of two main materials, corrugated iron, and steel. The cabinet thickness of a standard cabinet is usually 1.2mm-1.5mm, and a cabinet of poor quality will be more fragile by 0.8mm-1.0mm.

7) Electrical control cabinet

Motor control cabinet – as we all know, in almost all buildings, from civil to industrial, from factories to automation control systems, motor control panels are inseparable. Many types of motors, such as motors for pumping systems, motors for conveyor chains, motors for compressed air systems, etc. There are many ways to control the above motors such as direct start, star start, soft start, and inverter.

8) Synchronization cabinet

Synchronous electrical cabinets are designed to do the work of combining independently working generators or power sources to work together. It’s a high-tech solution designed to improve power reliability and optimize fuel economy. The biggest application of the synchronous electric cabinet is that when the mains power fails, the backup generator will automatically start, synchronize with each other, and share the load. Automatically monitor the load and control the number of transmitters running according to the load.

9) RMU cabinet

The English name RMU cabinet is the Ring Main Unit, which adopts a metal-enclosed structure design, gas-insulated SF6, and is used for medium-voltage power distribution systems below 36kV 630A.

• This type of cabinet is completely enclosed and all electrical switching elements are located in SF6 cylinders made of stainless steel. Thanks to this feature, it creates a safe product for the operator. Good moisture and dust resistance.

• The RMU cabinet is connected through the cable room using a circuit breaker, and the cables leading out from the transformer use a load circuit breaker with protective fuses.

• RMU cabinets are divided into 2 types according to customer requirements:

• Extensible cabinet (Extensible)

• Cabinets are not expandable (Compact)

• Equipment lifetime: >20 years.

• Stable operation in any harsh climate conditions (-250C ÷ + 400C)

• Products are manufactured in accordance with ISO 9001: 2000 and ISO 14001 standards.

RMU cabinets are used in small power distribution substations; medium-sized substations, high-voltage underground stations or overhead; wind power plants; hotels, shopping centers, conference centers, apartment buildings, and offices.

Non-electrical or mechanical components and electrical components make up an electrical cabinet.

1) Non-electrical components

- Rear Panel: This is a steel plate on which other components are mounted.

- DIN Rail: Standard-width steel rail that provides a mounting base for equipment. The term “DIN” is derived from the German Institute for Standardization.

- Wiring Conduit: This component helps route and organize cables and wires to power and connect various electrical devices.

2) Electrical components

- Main Breaker: This switch serves as the main point where power enters the cabinet and supplies power to all electrical equipment.

- Surge suppressors: Overvoltage protection devices protect all electrical components in the cabinet.

- AC Power Distribution: Consisting of multiple circuit breakers, this system acts as a hub where other devices that require AC voltage can be connected.

- Power Supply: This component converts the incoming AC voltage to DC voltage. Typical output voltages are 5V, 12V, and 24V DC.

- DC Power Distribution: Similar to AC power distribution, DC power distribution involves circuit breakers specially designed for DC voltage. These circuit breakers help deliver the correct DC voltage to the various components in the cabinet.

- Terminal Blocks: These are used as connection points for wires inside the cabinet. Terminal blocks can be used to connect two wires together, or as a point at which field instruments such as sensors or actuators are connected to an electrical cabinet. It is possible to have digital or analog terminal blocks.

- Ethernet Switch: This device supports communication between the various elements within the panel.

- Programmable Logic Controller (PLC): Instruments connected to the machine send and receive data through this component.

- Relays: These protect the PLC from overcurrent and at the same time enable digital outputs

Medium-voltage electrical cabinets are designed and manufactured according to strict quality management processes, with high stability and safe operation. Important electrical equipment for commercial and residential electrical construction. The cabinet structure ensures high safety: the cabinet is made of a 2mm thick steel plate, which is firmly fixed, and the position of the switch such as the cutter is reasonable, and it is protected by the inner wing of the cabinet.

The structure of the medium-voltage electrical cabinet includes: the cabinet body is made of about a 2mm thick plate, which is insulated and strong, and the switches are independently and reasonably arranged and are protected by the inner wing of the cabinet. Power plants, commercial buildings, and industrial plants use cabinets to house electrical equipment up to 24KV.

The following types of medium-voltage electrical cabinets are available:

Medium voltage cabinets: VCB, LBS, DS

Medium voltage ATS cabinet

Ring cabinet second

Medium voltage capacitor cabinet

The following are some features of medium voltage distribution cabinets:

- Manufactured according to IEC 62271-105 and IEC 60470 standards, rated voltage 12kV, indoor type, 3 poles

- For medium voltage motors, transformers, and capacitors

- Fully sealed contactor housing and 2.5 bar low SF6 air pressure, safe and reliable.

- Divided into separate dedicated compartments for increased safety and continuous operation

- Types of medium voltage contactors: There are two designs fixed type and movable type

- The contactor adopts SF6 combined with arc stamping technology-vortex arc technology-arc stamping and fast medium recovery, which limits the wear of the contacts.

- SF6 gas technology reduces arc duration and arc elongation for improved electrical durability

- Low switching ambient voltage prevents de-insulation of motor windings

- There are two types of contactors available for each need, the intended use is electrical latches and mechanical latches.

- Continuous monitoring of SF6 gas pressure (optional)

- Resistant to external impact for use in the harshest environmental conditions such as mining, oil, and gas

- Can be combined with fuses for added protection.

The medium voltage cabinet is used to cut off and protect medium voltage power supply lines. Medium-voltage power distribution cabinets are often installed in power plants, power transmission and distribution stations of power companies, or power distribution stations in industrial parks and residential areas.

- Understand the schematic diagram of the medium voltage ring main unit system to be installed

- Read and understand the secondary wiring diagrams for necessary measuring and protective equipment.

- Read the manufacturer’s installation and operating manual.

- Complete the electrical cabinet with the necessary accessories such as cable connectors, power cords, backup power supply, supports, and suitable portable machine tools.

- Installation: Follow the steps in the instruction manual for installation and operation. Use suitable hand mechanical tools.