Electrical circuits often use the terms switchgear and switchboard. Electrical contractors need to understand both terms in order to communicate well with their peers. There are many switchgear companies. Therefore, it is very important to understand these two terms correctly to choose the best switchgear company.

Project owners are often faced with the decision of whether to use switchgear or switchboard in low-voltage projects. While switchgear and switchboards may serve similar purposes, there are key differences that make them suitable for specific applications. We compare the two in this article.

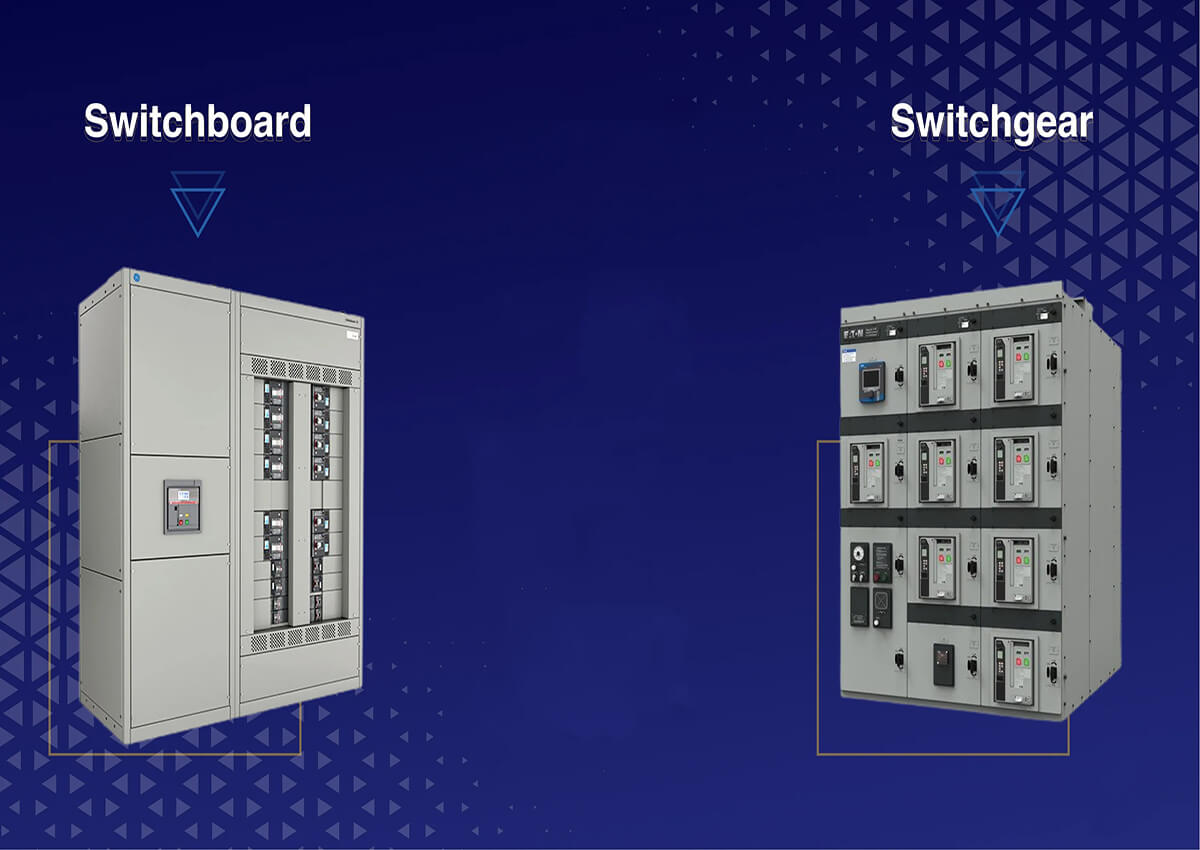

1. Switchgear and switchboard equipment

Switchgear and switchboards refer to the types of equipment used to manage and distribute electrical power while protecting circuits and equipment. Electrical systems are protected by disconnect switches, fuses, and circuit breakers.

As you can see, both switchgear and switchboards are power distribution devices. However, many features set them apart. To explain these variants, we’ll first look at the definition of each variant before delving into the characteristics that distinguish one from the other.

1) Definition of switchgear

A switchgear is a component or combination of electrical devices used to isolate or protect electrical circuits. Switchgear uses include automatically turning off and turning on the power in electrical systems, allowing electricians to break circuits for repairs, and monitoring electrical systems.

The switchgear can be an open-air device for the protection of overhead power lines, or it can take the form of an enclosed assembly in which the switchgear assembly is installed. These include switches, fuses, and busbars used to control, protect, and isolate parts of electrical systems in buildings and other facilities.

2) Definition of switchboard

Switchboards are electrical control assemblies with switches, circuit breakers, and fuses used to distribute electricity in a building. Switchboard assemblies may also include gauges, relays, and other electrical control and protection devices.

The switchboard can be a simple metal structure containing switches and safety devices mounted on a wall, or it can be a large freestanding structure controlling power distribution in large facilities.

2. Switchgear Vs. switchboard

We have looked at the definition, but what is the difference between a switchboard and a switchgear? There are many variations in terms of design, application, and components. They also include rated voltage, mounting location, and even cost. Taking a closer look at each difference, let’s see how they differ.

1) Switchgear vs. Switchboard: Design

The main difference between a switchgear and a switchboard is the design of the parts. Switchgear assemblies consist of serviceable withdrawable (full or partial) circuit breakers that have solid insulation to protect them from other parts.

Switchboard breakers, on the other hand, are usually bolted to the bus and are separated from other components only by air. This design makes the switchboard smaller but also means that the circuit breakers cannot be repaired, only replaced.

It is also worth noting that switchgear often uses a rear compartment for cable termination. With front terminals, switchboards are wall-mountable and smaller than switchgear.

2) Switchgear vs. switchboard: Voltage

Voltage rating is another major difference between switchgear and switchboards. Switchgear is rated for a wider range of voltages, ranging from a few volts to thousands of volts. For example, the voltage range of low-voltage switchgear can reach 1kv, while the voltage range of medium and high-voltage switchgear can reach 366kv and higher.

Electrical switchboards, on the other hand, are designed for lower voltages, usually below 600 V. For example, a typical residential switchboard is rated for 120/240 V. On the other hand, commercial and industrial facilities may have switchboards rated up to 600 volts.

3) Switchgear vs. switchboard: Standards and tests

Both devices are 2200-volt dielectric circuits and are tested slightly differently. One of the main differences between switchgear and switchboards is standards and tests. Switchgear with low-voltage circuit breakers is based on ANSI C37.20.1 and NEMA SG-3 standards.

The high-voltage switchgear is a long-circuit structure with a power factor of 15% capacity and 30 cycles. On the other hand, the switchboard is a short-circuit structure with a power factor of 20% and 3 cycles. It is used in insulated case circuit breakers and molded case circuit breakers according to NEMA PB-2 and UL-891 standards.

4) Switchgear vs. switchboard: Size

Size becomes an important factor in determining the type of equipment to be installed in a particular situation, making one type of equipment superior to another. The switchboard takes up less space and works primarily in front access. They are ideal for small electrical systems.

However, switchgear is different because they gain front and rear access in the event of a cable break. They take up more space and are ideal for developing larger circuits.

5) Switchgear vs. switchboard: Arc safety

Arc-containing switchgear uses more elaborate insulation methods such as air, gas, oil, solid dielectric, or even vacuum. In switchboards, some of these arc flash extinguishing techniques may not exist because they are not industry standard requirements.

However, while switchboards are not required to contain arcs, they may contain features that mitigate the effects of arc flash, such as arc-resistant switchboards.

6) Switchgear vs. switchboard: Cost

Switchgear assemblies are complex and robust structures that cost more than switchboards. In contrast to low-voltage MCCBs used in switchboards, switchgear uses withdrawable circuit breakers. These usually cost more.

Compared to switchboard circuit breakers, switchgear circuit breakers have a higher 30-cycle current withstand rating. The current withstand level is the highest instantaneous (0.5 second) fault current that a circuit breaker can withstand without damage.

7) Switchgear vs. switchboard: The structure type of the circuit breaker used

9) Switchgear vs. Switchboard: Applications

LV or low voltage switchgear is commonly used to control, protect, and isolate electrical equipment or circuits in residential and industrial environments such as factories, power plants, and mines. Therefore, it is usually installed on the secondary side of the mains input transformer to supply power to switchboards and other equipment.

Switchboard assemblies are commonly used to distribute electrical power in a building or structure. As such, you’ll typically find them in residential and commercial settings such as homes, offices, and shops. Some may even receive power from the switchgear device before feeding it to the loads within the facility.

3. How to choose between switchboard and switchgear?

When selecting power distribution equipment, construction managers and engineers often have to choose between switchgear and switchboards. If you are a facility owner, you may also be interested in knowing which equipment is right for your investment.

Overall, switchgear is best suited for situations where system integrity is critical, such as data centers, airports, and medical facilities. Power strips are best used on lower-level systems where outages are not a major concern. Due to its smaller size and lower cost, it is often an option when space and budget are the main constraints on a project.

4. Conclusion

Various aspects of switchgear and switchboards differ, including voltage levels, design, and application. We hope this electrical vs. switchboard article has given you a clearer understanding of the differences that exist between these two devices. Most importantly, you now understand when switchgear is required and when it is suitable for a switchboard.

Leave A Comment