Since their introduction in the 1960s, vacuum circuit breakers have been developing technology. In the market, you may find various VCB manufacturers, it is important to find the best High Voltage Circuit Breaker Manufacturer. A circuit breaker is a device that acts as a switch to interrupt a circuit in the event of a fault. This is done to prevent overloading the power supply, it interrupts the flow of electricity after a fault is detected.

Circuit breakers are used in hotels, commercial complexes, industries, buildings, and other fields and places. VCB circuit breaker is a circuit breaker with a vacuum as the main arc extinguishing medium. We will discuss the vacuum interrupter, VCB mechanism, and working principle in detail in this article. You will be able to find the ideal circuit breaker service this way.

1. What is VCB?

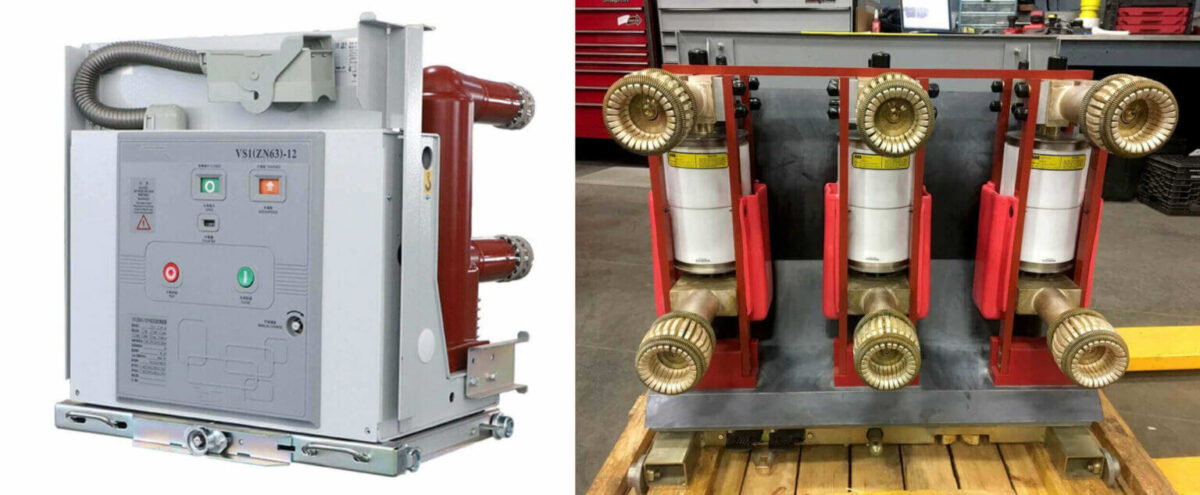

A VCB or Vacuum Circuit Breaker is a type of circuit breaker in which a vacuum is used as the quenching medium in the circuit. Primarily created for medium-voltage circuit breakers and high-voltage circuit breakers, the technology has been developed but is not yet commercially viable. It is a circuit breaker suitable for most standard voltage implementations.

The making and breaking of contacts and associated arcs all take place in a vacuum chamber. The operation carries the current and connects the interruption of the arc in a vacuum chamber called a vacuum interrupter. The reason why we use a vacuum is that a vacuum is an excellent arc extinguishing medium. Its performance is increased due to its high-insulating properties.

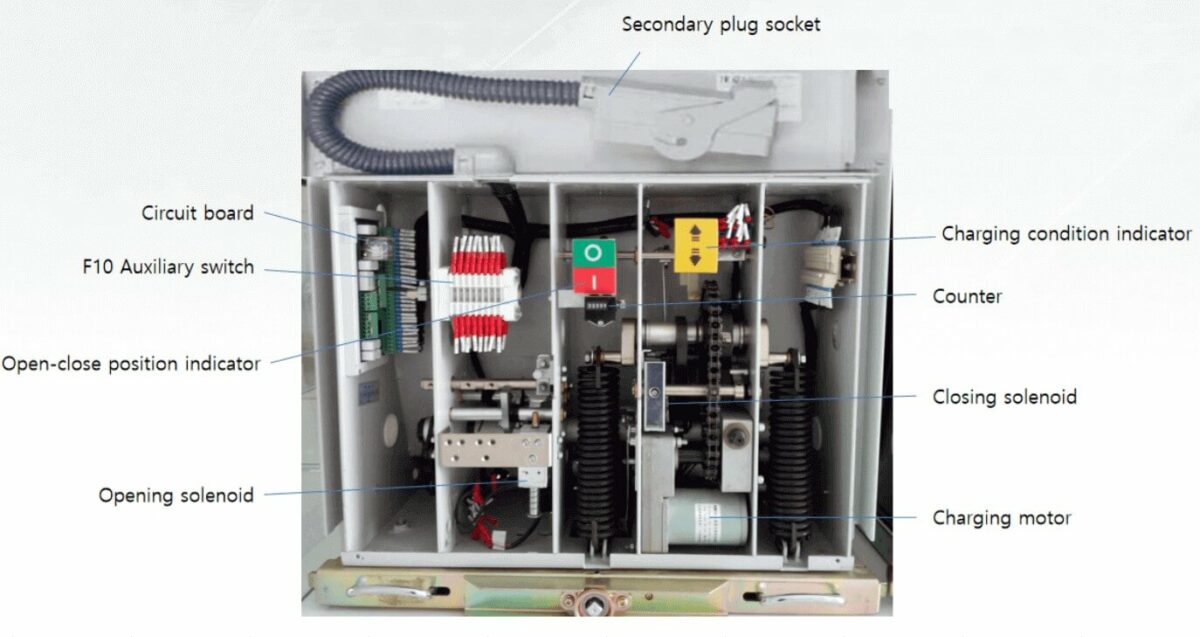

2. Structure of vacuum circuit breaker

You can consider vacuum circuit breakers to be fairly simple in construction compared to other types of circuit breakers. In the event of an overload, the VCB is divided into three parts that work together to cut power. This is the structure of a vacuum circuit breaker.

1. Outer layer

2. Arc shield placed in the interrupter

3. Fixed and moved contacts

4. Vacuum interrupter

1. Outer layer

Some of the outer layers of vacuum circuit breakers are made of glass. This setup ensures that the entire VCB unit is clearly visible from the outside. So if the glass turns cloudy and milky, it’s a clear sign that the breaker is releasing the vacuum. Therefore, the external shiny glass is very important to monitor the function of the circuit breaker after the operation. Some outer layers are made of metal to resist external corrosion and dust.

2. Arc shield

The arc shield is covered by an insulating casing. They cover the shield and prevent any condensation on the case. The arc shield prevents metal vapor from falling into the surface of the outer insulating enclosure. The arc shield holds and moves the contacts.

Copper-chrome and copper-bismuth alloys are considered ideal materials for creating VCB contacts. Contact material plays an important role in the performance of high-current circuit breakers. The steel interrupter is mounted symmetrically inside the ceramic insulator.

3. Moving contacts and moving contacts

The moving contacts are connected by means of stainless steel bellows. It is connected to the control mechanism. When sealing these contacts in an arc shield, the temperature is usually maintained at around 10 -6 Torr. The operating voltage determines the action of the moving contact. Typically, the moving contact moves a distance of about 5 to 10mm.

4. Vacuum interrupter

A vacuum interrupter is a seal in a vacuum reinforced inside the VCB. They cause any fault current to be interrupted. Within symmetrical ceramic insulators are steel arc chambers. The vacuum interrupter can maintain a vacuum pressure of 10-6 bar. The assembly takes place in a clean environment.

A vacuum circuit breaker’s performance is determined by the material of its current-carrying contacts. This explains the structure of the high-voltage vacuum circuit breaker. The construction of the circuit ensures long-term electrical strength and prevents any internal damage to the VCB components.

The vacuum chamber is permanently sealed to prevent leaks in the VCB circuit. For the outer body, ceramic or glass containers are used as insulators. The insulating layer acts as a protective layer for the circuit.

3. Working principle of vacuum circuit

Vacuum circuit breakers are engaged in outdoor environments ranging from 22kV to 66kV. They are suitable for most rural applications. When the circuit is broken for any reason, the moving contact moves away from the fixed contact, causing an arc between the contacts.

The arc is produced by the ionization of metal ions, and the reaction depends on the material of the contacts. When the contacts separate, they release a space-filling metal vapor. The vapor contains positive ions from the contact material. The steam helps eliminate the arc.

The rate of steam release is dependent on the current rate. When the current starts to drop, so does the amount of steam. The current is gradually reduced to zero, and the velocity of the steam is also gradually reduced. This causes the dielectric to recover its dielectric strength.

When the current voltage is high, the arc can focus on a small area, which causes the surface to evaporate quickly. Interruption is possible when the arc is in the spreading phase. Otherwise, the arc will strike again. After the arc is finally interrupted, the dielectric strength increases rapidly, which is unthinkable for a vacuum circuit breaker.

High-voltage vacuum circuit breakers are ideal for switching capacitors without restarting. The entire arc extinguishing process is greatly affected by the shape and material of the contacts: fixed contacts and moving contacts. In addition, it depends on how the metal vapor condenses.

It’s all about the construction and working of vacuum circuit breakers.

4. Virtual circuit application

VCB is considered to be one of the most reliable current interruption techniques for medium voltage current switchgear. Vacuum circuit breakers have the advantages of long life, high efficiency, safety, long operating life, and high breaking capacity. Due to its high performance and low performance compared to other technologies, new promising products are being developed.

Over the past few years, vacuum circuit breaker technology has been emerging and although its application is not feasible at a high commercial level, it is well suited for medium voltage applications. VCB technology is mainly used in medium voltage circuit breaker applications. Because vacuum circuit breakers are capable of handling high di/dt-dv/dt conditions and high currents, they are ideal for interrupting DC circuits.

It does not produce any harmful gas like SF6 circuit breakers. Therefore, they are ideal for the environment and humans. Due to their easy accessibility and simple circuit mechanism, vacuum circuit breakers are expected to be used in a broader range of applications in the future.

5. Conclusion

So, that’s all you need to know about the construction and working of a voltage circuit breaker. We’ve seen how vacuum circuit breakers work efficiently, how industrial circuit breakers work, and more.

How useful was this post?

Click on a star to rate it!

Average rating 5 / 5. Vote count: 2

No votes so far! Be the first to rate this post.

Leave A Comment